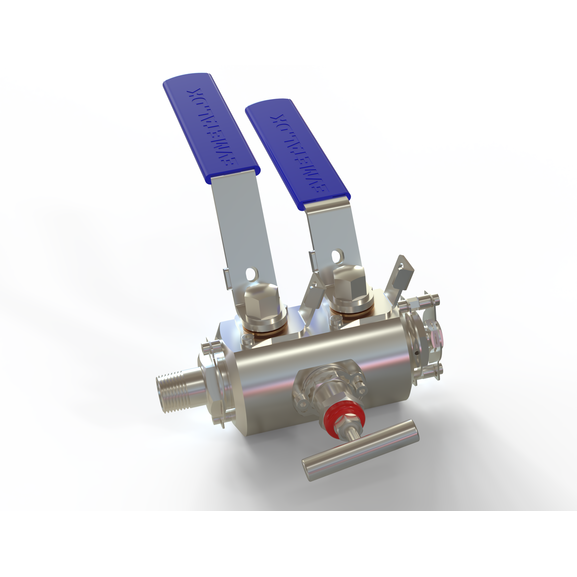

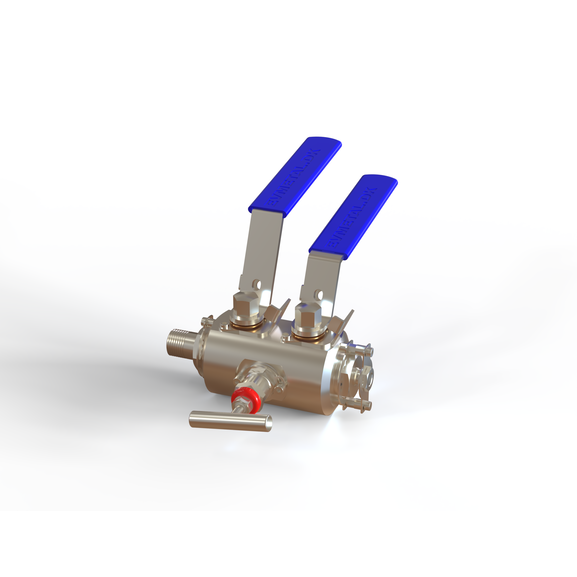

DBB valve with anti-vibration connection-ends.

Specifications

| Item number: | Dim: | Inlet: | Outlet: | Ventilate: | tMin. | tMax: | Max. Pressure: | Material: | Standard: |

|---|---|---|---|---|---|---|---|---|---|

| 1000-806 | 1/2" | 1/2" NPTM | 3/8" Cone/Thread | 1/2" NPTF | -20°C. | +130°C. | 6.500 Psig | EN 1.4404 | ASME B1.20.1 |

| 1000-805 | 1/2" | 3/4" Cone/Thread | 3/4" Cone/Thread | 1/2" NPTF | -20°C. | +130°C. | 6.500 Psig | EN 1.4404 | ASME B1.20.1 |

About the product

Minimize issues with leakpoints by changing to valves with anti-vibration mount connections.

If you are having issues with leaking valve ends due to equipment vibrations we suggest to consider valves and manifolds with anti-vibration valve end mounts. The mechanical lock of the valve ends prevent the valve ends from slowly un-screwing over time. Especially on un-manned oil-rigs it´s a well known problem with leaking valves. A problem that can be solved by instaling valves and manifolds with mechanical locked valve ends.

In the open waters, an un-manned oil-platform is serviced by fixed intervals. This is why understanding the role of anti-vibration connection mounts, and how to select them is fundamental for safety and efficiency. The system is running smoothly until the equipment begins to vibrate. Suddenly, there is the possibility of the valve ends to un-screw over time. This is a classic situation that no one wants in the middle of the sea. A situation where anti-vibration mounts could have helped.

What is anti-vibration connection-ends?

Valves with anti-vibration connection-ends from EV Metalværk are designed to lock the valve-ends into locked position so that it will stay in this position even though the valve is vibrating due to frequent equipment-vibration. E.i equpment on a wellhead installation. The anti-vibration connection-ends are critical for reducing the risk of the valve leaking from the valve ends over time.

Types of anti-vibration connection ends?

Our DBB valves are available with locked NPT or C/T connection-ends as standard, but they can be mounted with any type of tread according to customer request. Our anti-vabration connections-ends are suitable for instrument valves up to 1" without sacrificing the structural integrity of the valve design.

Why is anti-vibration connections important in offshore installations?

These components do much more than minimizing the risk of leaks. we believe that they are fundamental to the overall safety, efficiency, and regulatory compliance of offshore operations.

Safety First

Safety is paramount, especially at sea, and effective vibration control is key to ensuring it. Anti-vibration connection-ends play a crucial role in maintaining the structural integrity of an offshore oil & gas platform. Without proper anti-vibration connection-ends on your valves and manifolds the constant vibrations can lead to structural fatigue over time, causing critical components to fail during operations.

To discuss your specific needs, don’t hesitate to call us at +45 97 32 20 33. Our engineering dept. is ready to help you select the best valve or manifold for your application. We design and manufacture the valve or manifold to your data sheet and specifications.