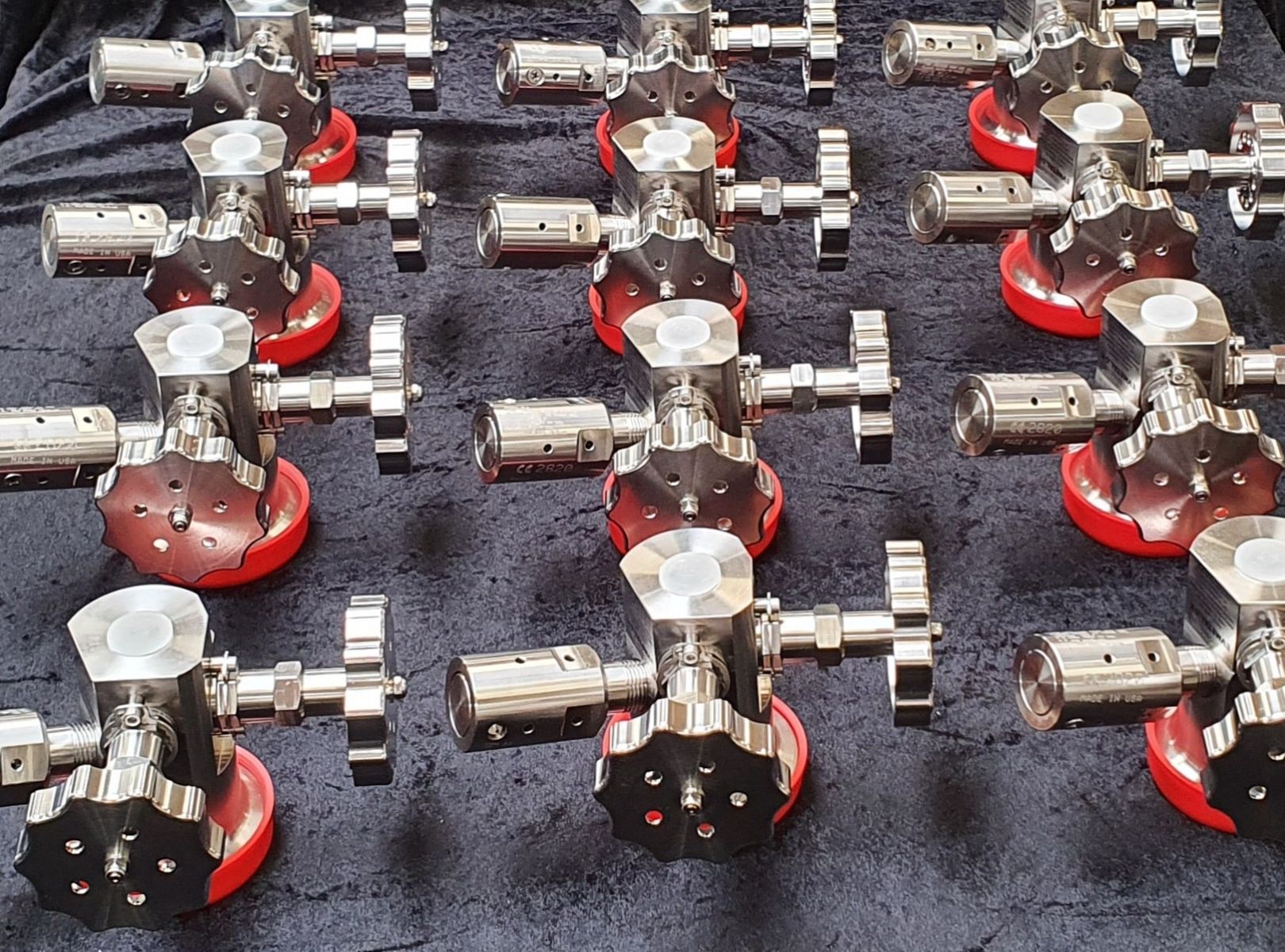

Offshore oil & gas valve solutions

In offshore wellhead environments, where corrosion is constant, space is limited, and lightweight valves are necessary, custom valve solutions can be critical for optimal topside wellhead system configurations.

Supporting offshore projects from the North Sea to the Persian Gulf, EV Metalværk® has over two decades of experience in designing and manufacturing custom valve solutions.

Offshore Client Collaboration

Our offshore client portfolio focuses on safety, durability, and long-term performance, backed by material expertise and international standards.

Our clients value our core principle of direct collaboration with our engineering department. This ensures no information is lost and shortens the path to the optimal valve solution. The valve is designed either according to a fixed data sheet or according to other client demands and specifications. With engineering and manufacturing under one roof, we ensure optimal conditions—even for fast-track projects.

Applications in Offshore Production

EV Metalværk® valve products are engineered to meet the demands of offshore upstream production and transport, including wellheads, chemical injection, flowline isolation, process lines, and pressure control.

Offshore valve portfolio

We offer a range of high-performance valve products tailored to offshore use:

Global Reach

in offshore

Our offshore valve systems are trusted by customers operating in:

- The North Sea

- The Persian Gulf (Quatar, Abu Dhabi)

- Asia (Malaysia)

With proven performance in demanding regional standards and environmental conditions.

Material expertise and offshore standards

Our valves are designed and built using corrosion-resistant materials such as AISI316, Duplex, Super Duplex, and 6Mo alloys. These are individually selected for optimal long-term performance and durability in aggressive saltwater conditions where crevice corrosion is a constant risk.

All products can be manufactured and tested in accordance with offshore industry standards including API 6A, API 6D, NORSOK M-650, ISO 10497, and the Pressure Equipment Directive (PED).

FAQ

Offshore operations rely on a range of valve types such as ball valves, needle valves, check valves, and DBB valves. These are selected according to process requirements, safety considerations, and spatial constraints.

Valves are constructed using alloys like Duplex, Super Duplex, and 6Mo, and are often coated or surface-treated to withstand chloride-induced corrosion, in compliance with offshore standards such as NORSOK and API. EV Metalværk® strives to design valves and manifolds that avoid the need for additional surface painting. We achieve this through our patented Anti-Crevice Corrosion designs.

A DBB valve provides two isolation barriers and a bleed valve in between. It allows for maintenance, testing, and safe depressurization without full system shutdown – especially in critical applications such as chemical dosing, test points, or hydrocarbon containment.

Surface Wellhead - offshore oil and gas

A wellhead is the equipment assembly located at the surface of an oil or gas well, responsible for regulating extraction, preventing leaks, and controlling pressure. It essentially acts as the interface between the wellbore and the surface infrastructure. The wellhead includes components like valves, spools, and casing hangers. The primary purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings that run from the bottom of the oil well sections to the surface pressure control equipment. Wellheads are typically welded onto the first string of casing, which has been cemented in place during drilling operations, to form an integral structure of the well.

A wellhead works by providing a structural and pressure-containing interface for the drilling and production equipment at the surface of the well. The wellhead is connected to the casing or tubing that runs down the wellbore, and it seals the annular space between the wellbore and the casing or tubing.

Oil and gas wellhead equipment can be divided into three types: flowing wellhead equipment, pumping wellhead equipment, and gas wellhead equipment. The same principle of well tubing suspension applies to all three types.

A wellhead located on a production platform is called a surface wellhead. If the wellhead is located beneath the water, it is referred to as a subsea wellhead or mudline wellhead.

Christmas tree for offshore oil and gas

A Christmas tree is installed on the wellhead after the drilling process is completed. It is primarily used to control the flow of oil or gas into and out of a well during production. A Christmas tree consists of a series of valves, spools, gauges, and chokes.

Christmas trees (X-Mas trees) are used on both surface and subsea wells, with their primary function being to control the flow of oil or gas from the well. When the well and facilities are ready to produce and receive oil or gas, the X-Mas tree valves are opened, and the formation fluids proceed through a flowline.

Kill Wing Valve

In the context of oil and gas wells, a kill wing valve on a Christmas tree is a specialized valve used for injecting fluids into the well to control pressure and potentially kill the well—meaning to shut off production. This valve is located on the left-hand side of the tree and is often manually operated. Its primary function is to inject fluids like drilling mud, completion fluids, or other chemicals into the well. This valve is used during well interventions, repairs, and sometimes for initial start-up.

Swab Valve

A swab valve is the topmost valve on a wellhead’s Christmas tree. It provides access for well interventions and maintenance without needing to shut down production. It allows for the insertion of tools such as wireline, coiled tubing, and snubbing units. The swab valve is essential for routine maintenance and troubleshooting, offering access to the wellbore for operations like logging, workovers, or repairs. It enhances safety by enabling emergency interventions without full isolation of the well. The swab valve is located at the top of the Christmas tree, which is a vertical assembly of valves and fittings that controls the flow of oil or gas from the well.

Sub-Surface Safety Valves - SSSV

SSSVs are a crucial safety feature in well completion, protecting personnel, the environment, and ensuring well control. A Subsurface Safety Valve (SSSV) is a fail-safe device installed in the wellbore to automatically shut down the well in case of an emergency, preventing uncontrolled fluid flow. These valves are strategically positioned in the well's tubing string and can be either wireline-retrievable or tubing-retrievable. SSSVs close automatically when a pressure drop occurs, indicating a potential well control problem or damage to surface equipment. This process, known as wellbore isolation, prevents fluids from rushing up the tubing, thereby maintaining control over the well.

The Upper Master Valve

The upper master valve is a critical safety component on an oil and gas well's Christmas tree, acting as a primary isolation valve. It is designed to quickly shut off well flow in emergency situations, preventing leaks and environmental damage. While the lower master valve is typically used for normal production, the upper master valve provides a backup and contingency option.

Primary Isolation

The upper master valve is one of the main valves used to completely shut off the flow of oil and gas from the wellbore.

Safety and Emergency Response

It is a crucial safety feature, enabling operators to quickly isolate the well in case of an emergency like a leak or blowout.

Backup to the Lower Master Valve

The upper master valve is often used as a backup to the lower master valve, which is typically in use during normal production.

Redundancy and Flexibility

Having both an upper and lower master valve provides operators with greater flexibility and enhances safety measures.

Hydraulically Operated

The upper master valve is often hydraulically actuated, allowing for remote and quick operation in emergency situations.

Fail-Safe Design

Hydraulic tree wing valves, including the upper master valve, are often designed to be fail-safe closed, meaning they require active hydraulic pressure to stay open.

Master Valve - Lower Master Valve

In oil and gas operations, the term "master valve" refers to a critical valve on the wellhead or Christmas tree that controls the flow of fluids from the well. It is essentially a gate that can shut off the entire production stream. Master valves are typically positioned on top of the Christmas tree and are designed to be primary isolation valves. Two master valves are often installed for redundancy, with one used for routine operations and the other as a backup.

Function

The primary function of a master valve is to control the flow of oil, gas, or other well fluids from the well. It is a critical component for well control and safety.

Location

Master valves are typically located on the wellhead or Christmas tree, which is the piece of equipment that connects to the wellhead and controls the flow of fluids.

Redundancy

Due to their critical role in well control, many Christmas trees have two master valves—one for routine use and one for backup or emergency situations.

Emergency Use

In emergency situations, the master valve can be closed quickly to shut off the well's flow, providing a vital safety measure.

Types

There are different types of wellhead valves, including master valves, wing valves, and swab valves, each with specific functions related to well control and intervention.

Connect with EV Metalværk

EV Metalværk, established in 1932, is a reliable supplier of high-performance industrial fittings and valves. Based in Ringkøbing, Denmark, we combine in-house engineering, precision manufacturing, and global sales under one roof. Our team of 40 skilled employees operates a specialised CNC machining facility 24/7, ensuring consistent quality and efficiency. With ISO 9001:2015 certification, we guarantee top standards and timely delivery.

Whether you require standard solutions or custom-engineered components, our experienced team is ready to assist. Contact us today to discuss your requirements. You can reach our offices in Denmark or Germany, or connect with our local distributors in Malaysia and Abu Dhabi. We look forward to working with you.